Styrocut

Styrocut is a versatile product that is made up of EPS (expanded polystyrene) styrofoam. This material can be used to create a wide range of shapes and figures using a CNC (Computer Numerical Control) machine. Whether you’re looking to create animal shapes, decorations for events, thermostat design, or construction cornices, Styrocut can be an excellent choice for your project.

- Cost Effective

- Lightweight and durable properties

- Strong

- Easy to handle

- Create any shape and design

- Environmentally friendly

Introduction:

In Pakistan, the utilization of StyroCut technology has revolutionized precision cutting and expanded the possibilities in various industries. StyroCut, a cutting technique using hot wires or CNC machines, has gained popularity for its ability to precisely shape Expanded Polystyrene (EPS) foam materials.

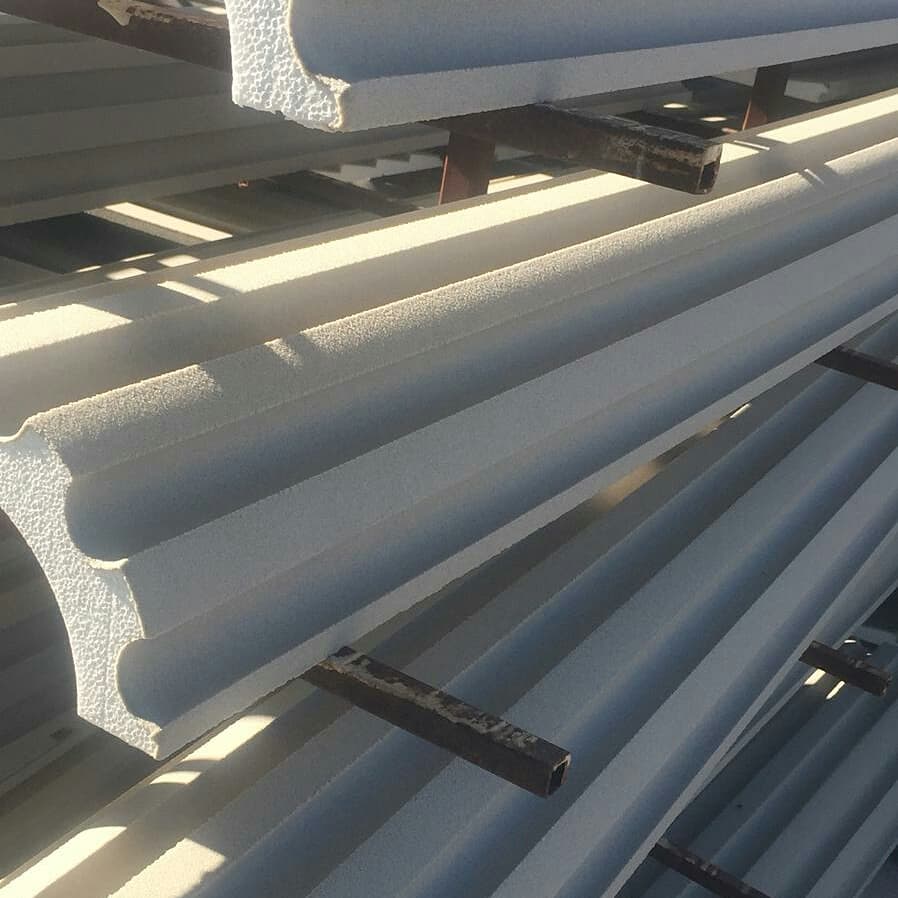

Architectural and Construction Applications:

StyroCut has become a game-changer in the architectural and construction sectors in Pakistan. EPS foam panels cut with precision using StyroCut can be used to create intricate decorative elements, including cornices, mouldings, and architectural facades.

The versatility of StyroCut enables architects and builders to realize complex designs with ease, giving structures a distinctive and visually appealing aesthetic. Additionally, StyroCut enables the creation of lightweight and durable concrete moulds, facilitating the construction process and reducing material costs.

Artistic Sculptures and Installations:

Artists in Pakistan have embraced StyroCut to bring their creative visions to life. EPS foam serves as an ideal material for sculptors, as it can be easily shaped and carved using StyroCut.

The precise and intricate cuts achieved with this technology allow artists to explore new dimensions and create stunning sculptures, art installations, and props for exhibitions, events, and theatrical performances. The lightweight nature of EPS foam also makes transportation and installation of large-scale art installations more convenient.

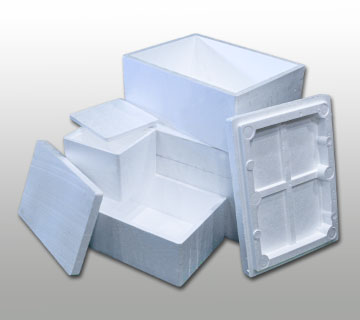

Packaging and Product Design:

The precision cutting capabilities of StyroCut have found applications in product packaging and design. EPS foam packaging inserts created with StyroCut ensure secure transportation and protection of delicate and fragile items, such as electronics, glassware, and medical equipment.

The customized shapes and sizes achieved allow for optimal fitting and minimal movement during shipping. Moreover, it enables the production of bespoke packaging designs, enhancing product presentation and branding.

Advertising and Event Decorations:

StyroCut has made a significant impact in the advertising and event industries in Pakistan. EPS foam cutouts and 3D logos created are commonly used for signage, billboards, and promotional displays.

The precise detailing achieved adds a professional and eye-catching touch to advertising campaigns. In event decorations, StyroCut enables the creation of intricate backdrops, stage props, and themed decorations, providing immersive and visually stunning experiences for attendees.

Set Design and Production:

The film, television, and theatre industries in Pakistan have embraced StyroCut for set design and production. EPS foam sheets cut with precision are transformed into realistic and elaborate scenic elements, such as building facades, landscapes, and props.

It allows for efficient production timelines and cost-effective set designs, enhancing the overall visual impact of productions while providing a safe and lightweight alternative to traditional set materials.

Manufacturing and Prototyping:

StyroCut has found applications in manufacturing and prototyping processes in Pakistan. EPS foam cut with precision serves as an affordable and versatile material for creating prototypes of various products.

It enables engineers, designers, and manufacturers to test designs, assess functionality, and make necessary modifications before proceeding to final production. The speed and accuracy streamline the prototyping phase, reducing development time and costs.

Insulation and Soundproofing Solutions:

Beyond its precision cutting capabilities, it also contributes to insulation and soundproofing solutions. EPS foam panels cut with this can be used for thermal insulation in buildings, reducing heat transfer and improving energy efficiency. Additionally, the sound-absorbing properties of EPS foam make it an excellent choice for soundproofing applications, such as recording studios, home theatres, and commercial spaces, ensuring optimal acoustic environments.

Conclusion:

The advent of StyroCut technology has transformed the cutting and shaping of EPS foam materials in Pakistan, opening up a world of possibilities across various industries. From architectural design and art sculptures to packaging, advertising, and manufacturing, StyroCut’s precision cutting capabilities have expanded creative horizons and improved efficiency.

As it continues to evolve, Pakistan embraces a future where intricate designs, precise cuts, and innovative applications become the norm, revolutionizing industries and inspiring creativity.

Electronics and Home Appliances

Pharmaceuticals