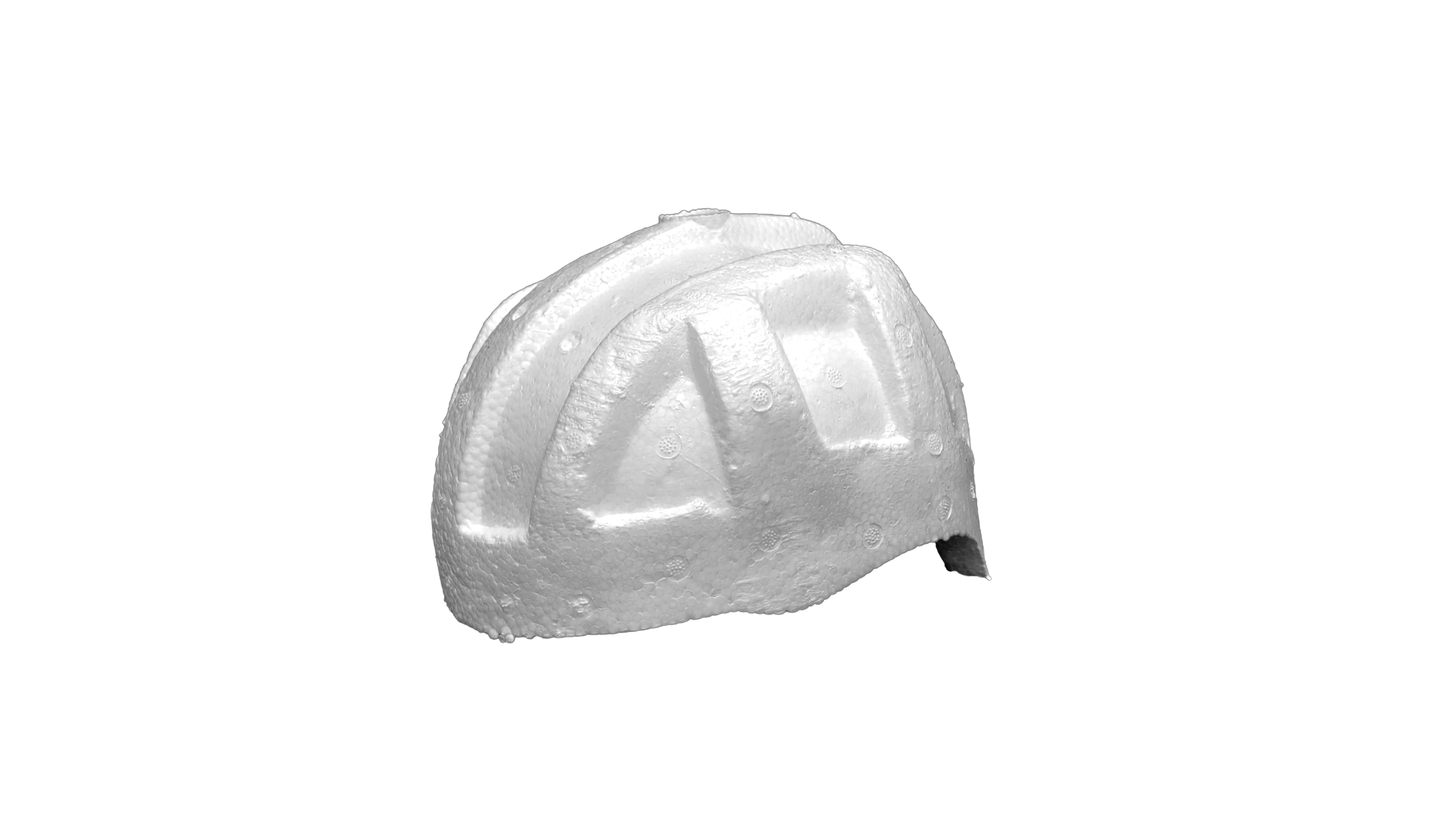

Electronics and Home Appliances

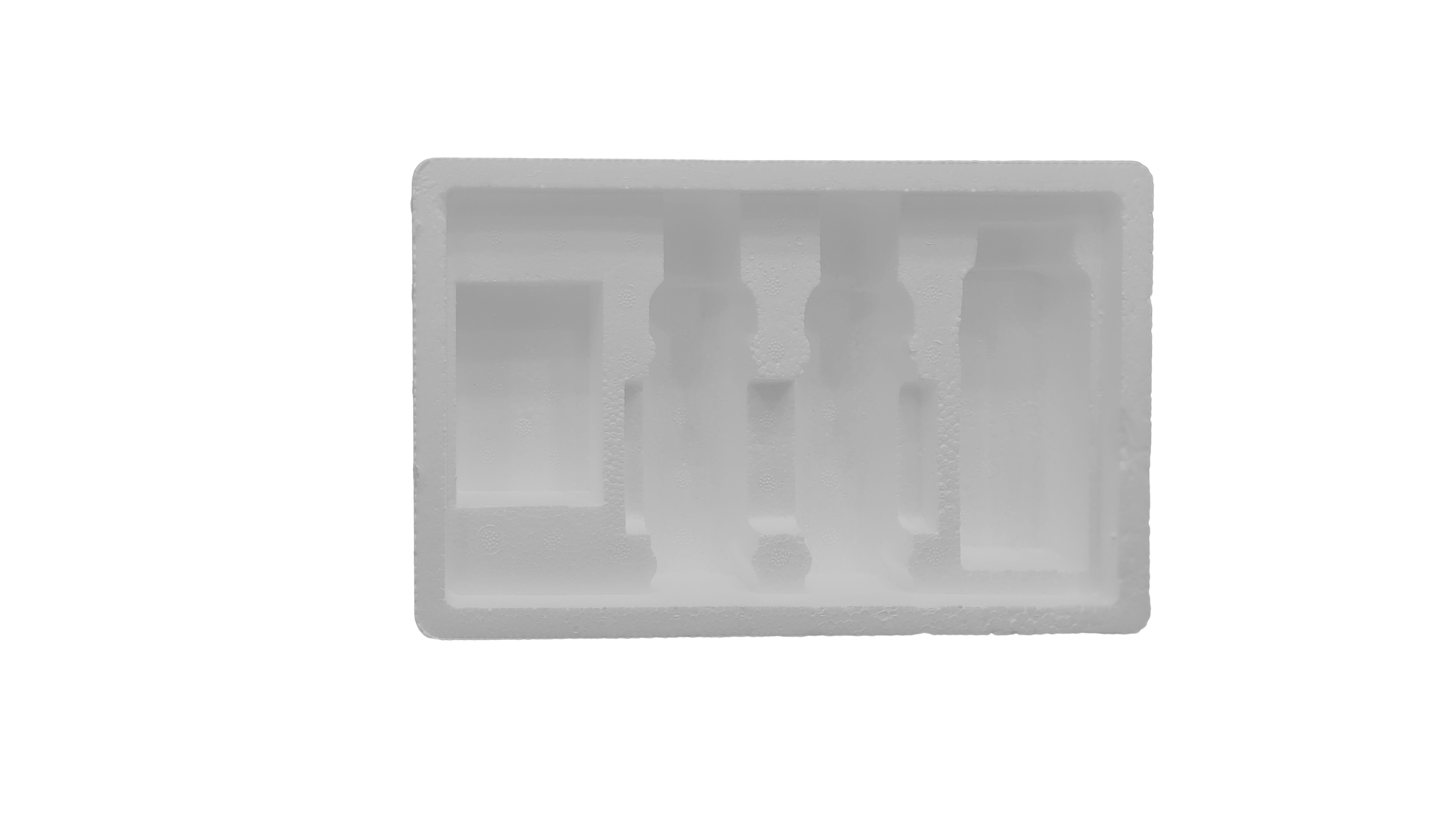

Pharmaceuticals

Eps Packaging

Discover the power of Eps Packaging | Thermopore Packaging in safeguarding your products during transit. Explore their exceptional cushioning, insulation, and eco-friendly benefits. Elevate your packaging strategy with these versatile solutions. When it comes to packaging, protection is paramount. EPS packaging and Thermopore packaging have emerged as dynamic solutions for ensuring the safe transit of products across various industries. Derived from expanded polystyrene (EPS) foam, these packaging options offer a winning combination of exceptional cushioning, insulation, and eco-friendly attributes. In this comprehensive blog post, we will delve into the world of EPS packaging and Thermopore packaging, exploring their features, advantages, applications, and environmental benefits.

Understanding EPS Packaging and Thermopore Packaging:

EPS packaging and Thermopore packaging both utilize expanded polystyrene (EPS) foam as the primary material. Foam is created by expanding polystyrene beads, resulting in a lightweight and resilient foam structure. EPS packaging and Thermopore packaging harness the unique properties of EPS foam to provide superior protection against shocks, vibrations, and temperature fluctuations.

Key Features of Eps Packaging | Thermopore Packaging

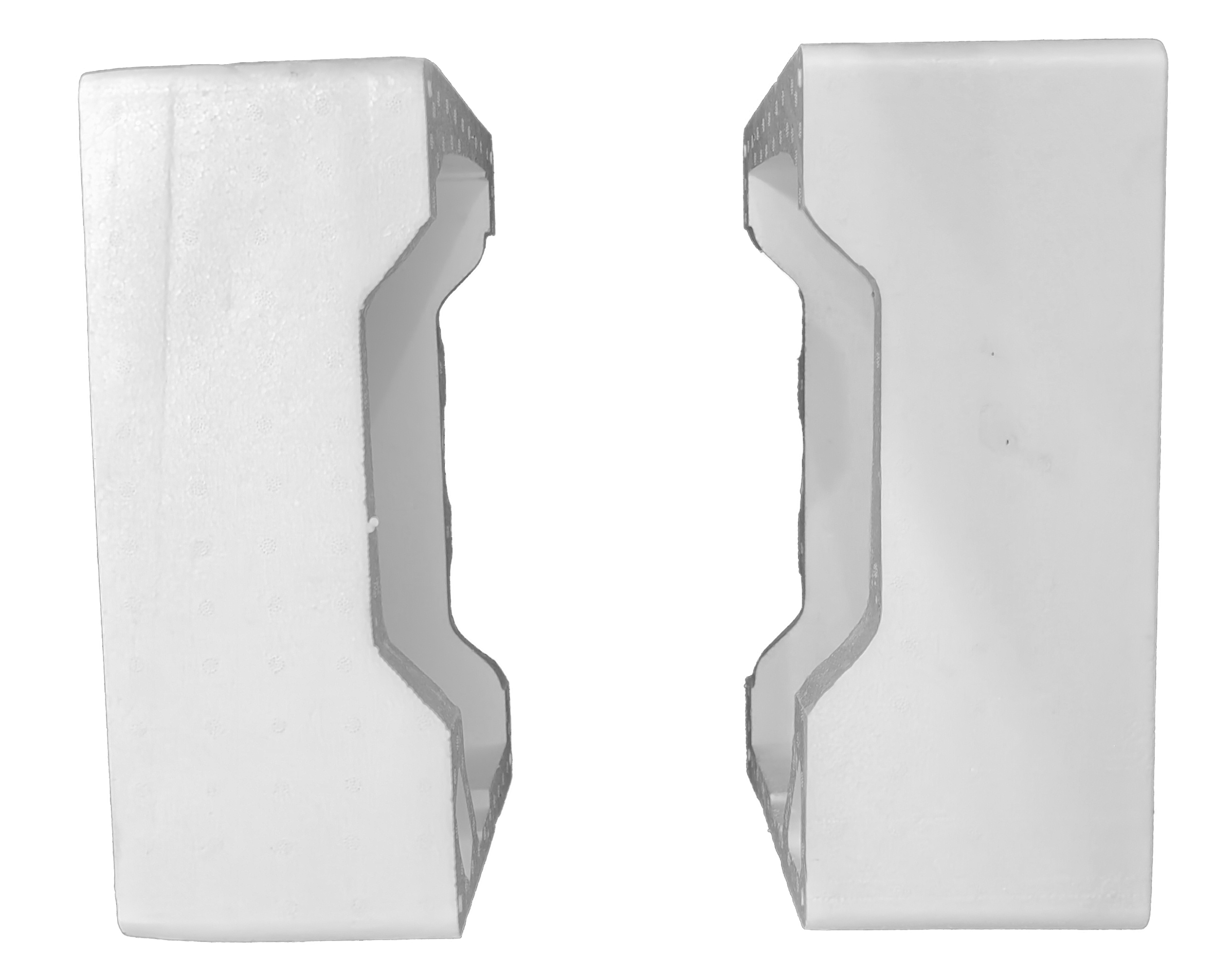

a) Cushioning and Shock Absorption:

EPS foam is renowned for its exceptional cushioning and shock absorption properties. EPS packaging and Thermopore packaging effectively mitigate the risk of damage during transit, ensuring products arrive in pristine condition.

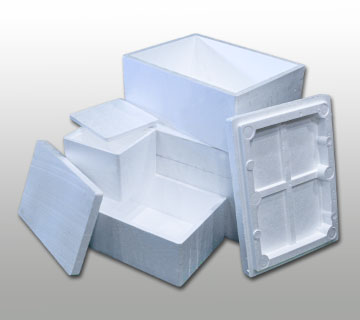

b) Thermal Insulation:

EPS foam possesses excellent thermal insulation properties, making EPS packaging and Thermopore packaging ideal for temperature-sensitive goods. These packaging solutions create a protective barrier, guarding against temperature fluctuations and preserving product integrity.

c) Lightweight and Cost-Effective:

EPS packaging and Thermopore packaging are lightweight, which contributes to cost savings during transportation. The reduced weight minimizes shipping expenses while maintaining excellent protective capabilities.

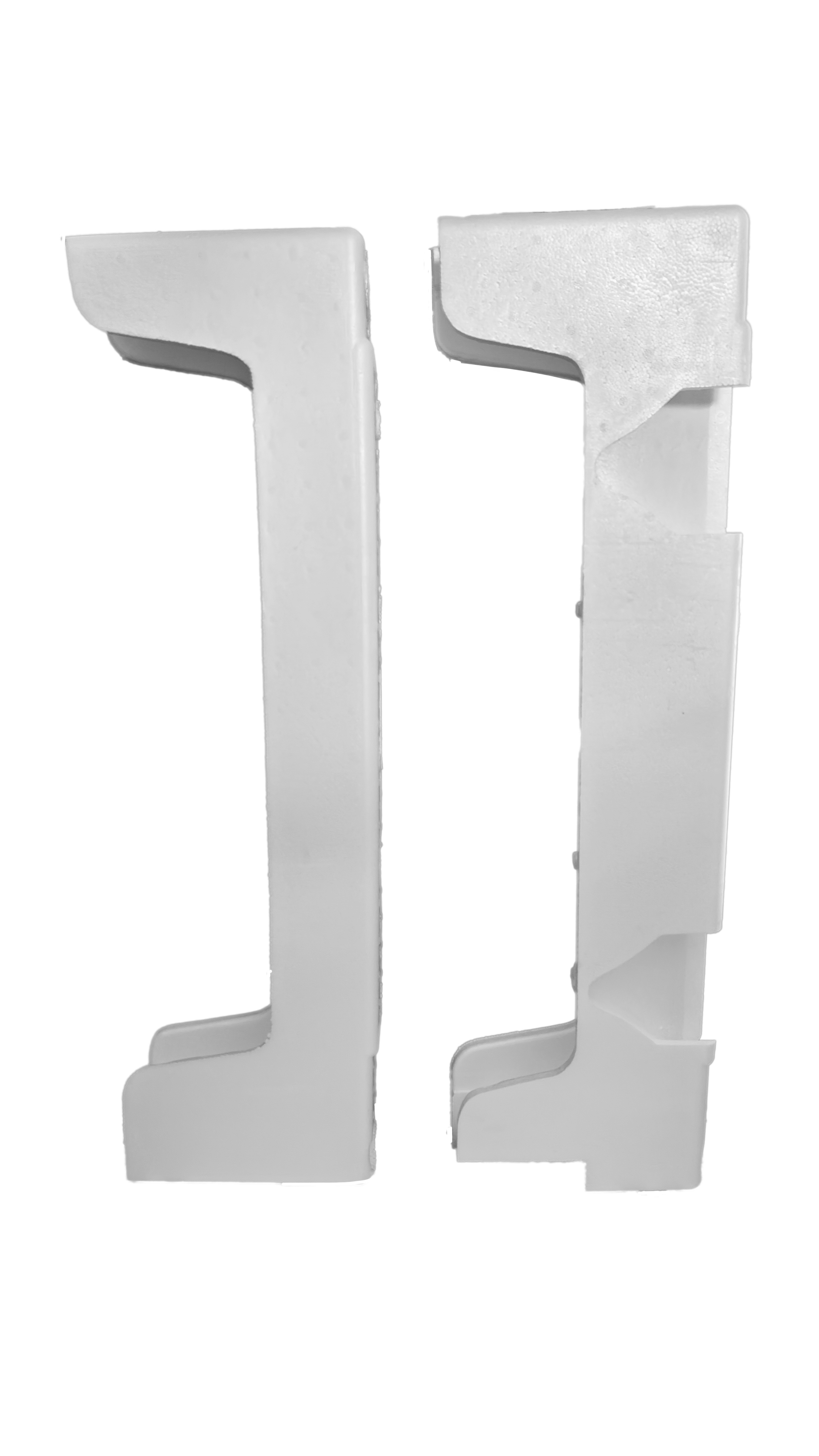

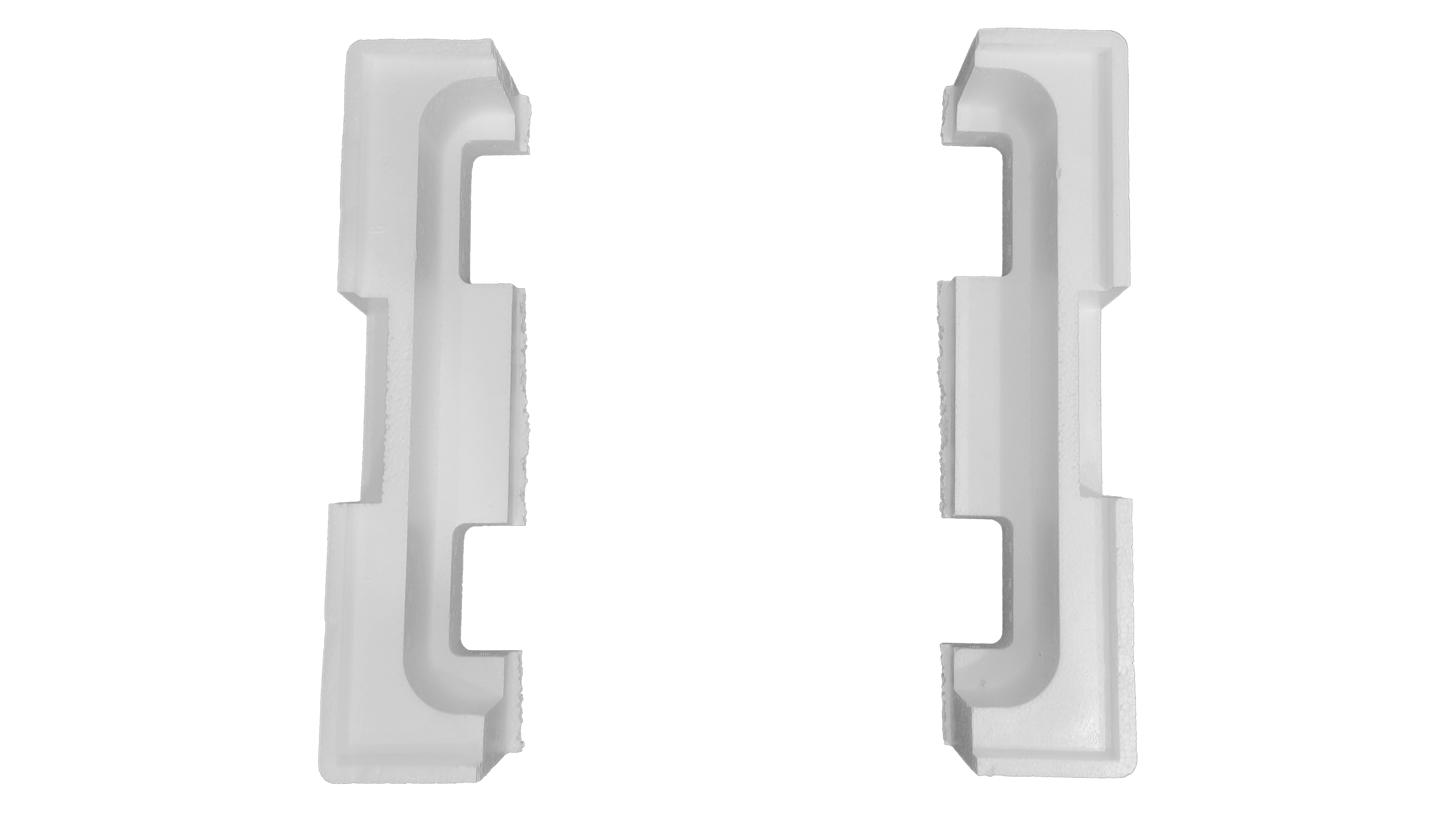

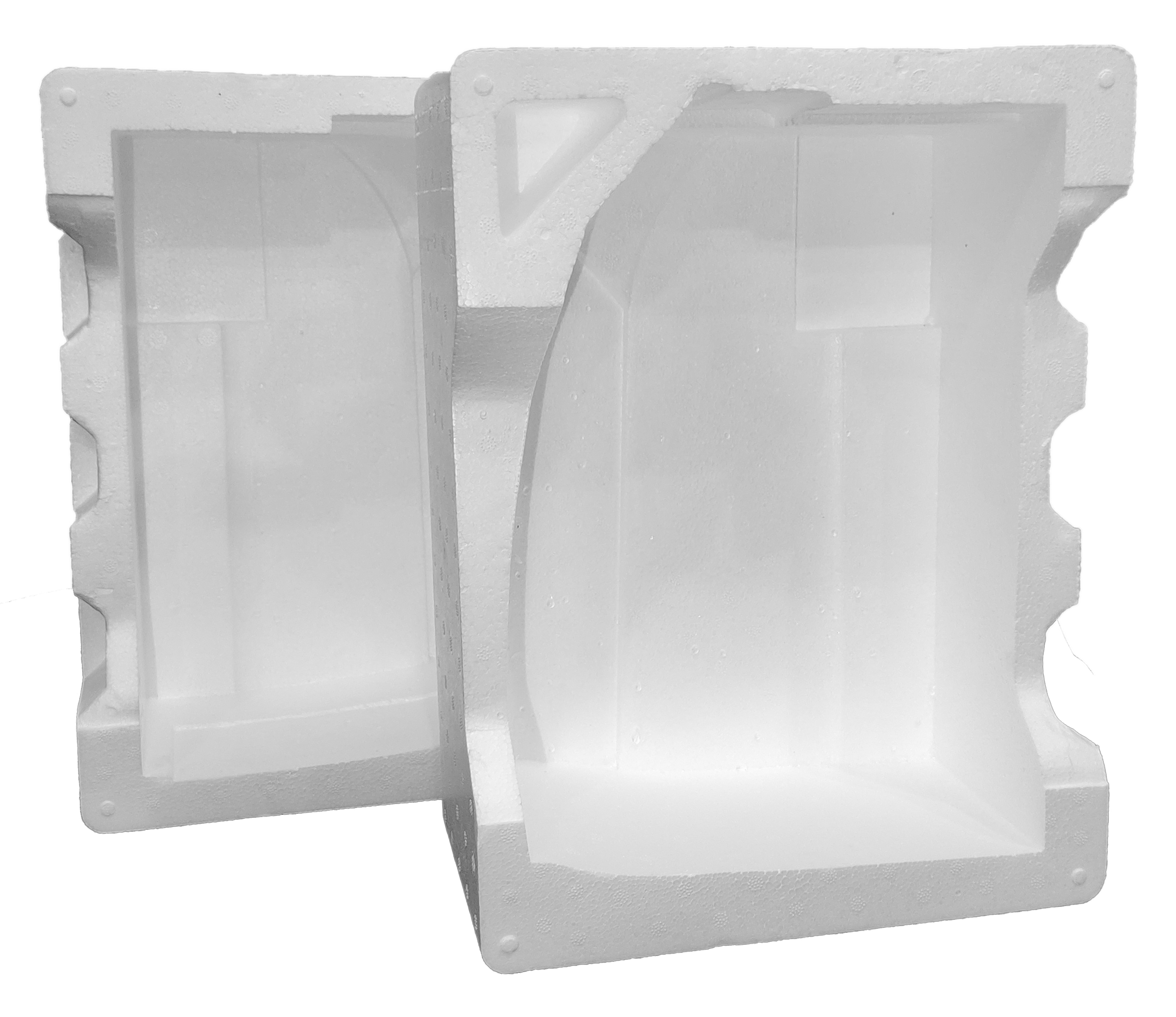

d) Versatility:

EPS foam can be easily moulded and shaped, allowing for customized packaging solutions tailored to specific products. EPS packaging and Thermopore packaging can accommodate various shapes, sizes, and complexities, making them suitable for a wide range of industries.

e) Moisture Resistance:

EPS foam’s closed-cell structure inherently repels moisture, protecting products from potential water damage during transit. This moisture resistance ensures the preservation of goods, particularly in humid or wet environments.

f) Environmental Sustainability:

EPS foam used in EPS packaging and Thermopore packaging is recyclable. It can be collected, processed, and reused to create new foam products or other applications, contributing to a more sustainable and circular economy.

Applications of EPS Packaging and Thermopore Packaging

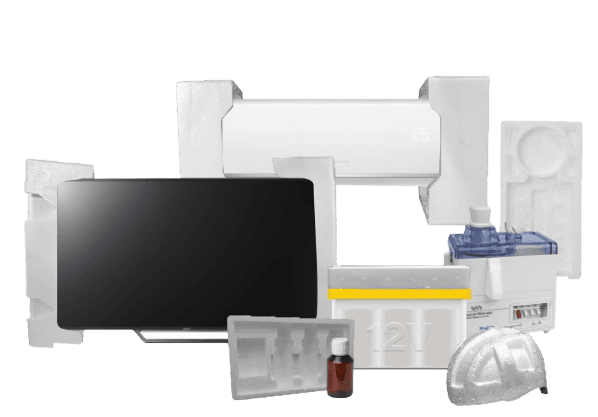

a) Electronics and Technology:

EPS packaging and Thermopore packaging offer optimal protection for delicate electronic devices, ensuring safe transportation and minimizing the risk of damage from impacts or vibrations.

b) Pharmaceuticals and Healthcare:

The pharmaceutical industry relies on EPS packaging and Thermopore packaging to preserve the quality and efficacy of sensitive medications and healthcare products during distribution.

c) Food and Beverage:

EPS packaging and Thermopore packaging play a crucial role in maintaining the freshness and temperature control of perishable food items, preventing spoilage and ensuring safe delivery to consumers.

d) Retail and E-commerce:

EPS packaging and Thermopore packaging are indispensable for the retail and e-commerce sectors, providing reliable protection for products during shipping, reducing returns, and enhancing customer satisfaction.

e) Industrial and Automotive:

These packaging solutions are widely used in the industrial and automotive sectors to safeguard components, machinery parts, and fragile equipment from potential damage during transportation.

f) Construction and Building Materials:

EPS packaging and Thermopore packaging are utilized for protecting construction materials, such as glass panels, tiles, and fragile building components, ensuring their safe delivery to construction sites.

Environmental Advantages of EPS Packaging and Thermopore Packaging

a) Recycling and Reusability:

EPS foam used in EPS packaging and Thermopore packaging can be recycled and repurposed, reducing waste and minimizing environmental impact.

b) Resource Efficiency:

The production of EPS foam requires fewer raw materials and energy compared to alternative packaging materials, making EPS packaging and Thermopore packaging a resource-efficient choice.

c) Reduced Carbon Footprint:

The lightweight nature of EPS packaging and Thermopore packaging reduces carbon emissions during transportation, contributing to a greener and more sustainable supply chain.

d) Durability and Longevity:

EPS packaging and Thermopore packaging’s durability ensures a longer lifespan, reducing the need for frequent replacements and minimizing waste generation.

Conclusion

EPS packaging and Thermopore packaging have revolutionized the protective packaging landscape. With their lightweight nature, cost-effectiveness, and versatility, EPS packaging and Thermopore packaging cater to diverse industries, ensuring products reach their destination intact. Embrace the dynamic duo of EPS packaging and Thermopore packaging to elevate your packaging strategy and safeguard your products with confidence.