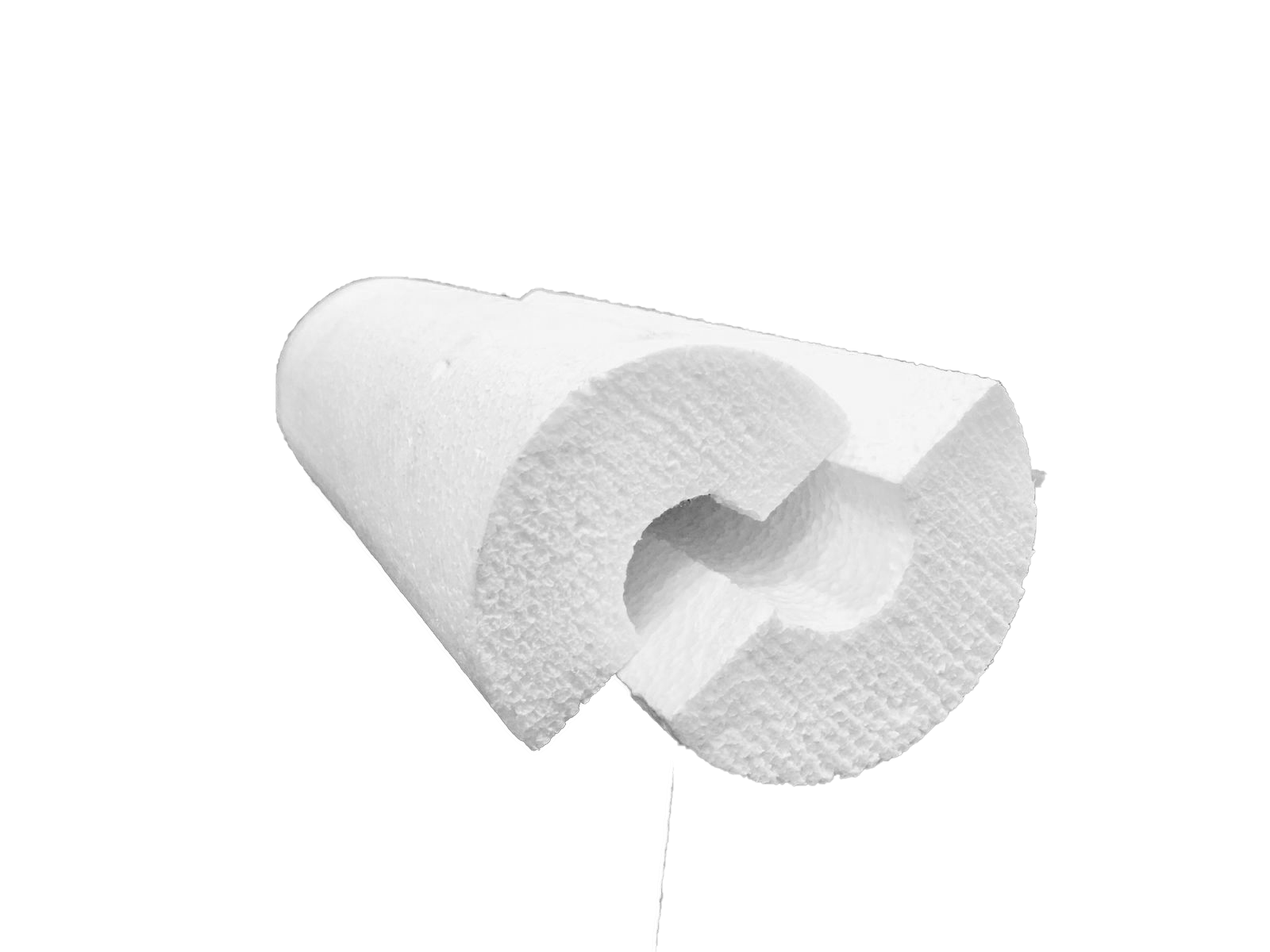

Pipe Insulation

I. Understanding the Function of Pipe Insulation

Pipe insulation serves multiple functions, all of which contribute to the overall performance and longevity of a plumbing system. Let’s delve deeper into each of these functions:

Thermal Insulation:

The primary purpose is to prevent heat transfer. Whether it’s hot water or steam pipes, insulation provides a layer of thermal resistance, minimizing heat loss and ensuring that the desired temperature of the fluid being transported is maintained. By reducing heat loss, pipe insulation helps conserve energy and lowers utility costs. It also prevents condensation from forming on cold water pipes, reducing the risk of water damage and mould growth.

Freeze Protection:

In colder climates, it acts as a protective shield against freezing temperatures. When pipes are exposed to sub-zero temperatures, the water inside them can freeze and expand, leading to pipe bursts and costly damages. By insulating pipes, the insulation material slows down heat transfer, effectively preventing water from freezing. This safeguard protects the plumbing system and prevents disruptions to the building’s occupants.

Energy Efficiency:

Insulating pipes can significantly improve energy efficiency, especially for long-distance pipelines or in industrial settings where large volumes of fluids are involved. The insulation helps maintain the desired temperature throughout the transportation process, reducing the need for additional heating or cooling. By minimizing heat loss and ensuring efficient energy usage, pipe insulation plays a vital role in sustainable practices and cost savings.

II. Qualities of Good Pipe Insulation

Not all pipe insulation is created equal. To ensure optimal performance and longevity, it is important to consider the following qualities when selecting insulation for your pipes:

Insulation Material:

There are various materials used for pipe insulation, each with its own unique set of properties. Standard options include foam, fibreglass, rubber, and mineral wool. The choice of material depends on factors such as temperature range, moisture resistance, fire safety, and cost-effectiveness. Consulting with insulation professionals can help determine the most suitable material for your specific needs, ensuring efficient insulation performance.

Thermal Conductivity:

A good pipe insulation material should have low thermal conductivity. This means it effectively resists heat transfer, minimizing energy loss and maintaining the desired temperature within the pipes. Materials with low thermal conductivity, such as closed-cell foam or fibreglass, are often preferred for their ability to provide efficient insulation.

Moisture Resistance:

Moisture can negatively impact the performance and durability of insulation. Therefore, selecting an insulation material that has good moisture resistance is crucial, particularly in areas prone to high humidity or condensation. Rubber or closed-cell foam insulation tends to offer superior moisture resistance, preventing water damage and inhibiting the growth of mould or mildew.

Fire Safety:

When selecting pipe insulation, it is essential to consider the fire safety rating of the material. Insulation with a high fire resistance rating can help prevent the spread of flames in case of a fire incident. Fire-resistant materials, such as mineral wool or specially treated foam, provide an added layer of protection and are recommended for installations where fire safety is a concern.

Ease of Installation and Maintenance:

Efficient installation and maintenance processes can save time and effort. Opt for pipe insulation that is easy to install, ensuring a proper fit and secure coverage. Additionally, insulation that requires minimal maintenance over its lifespan will help reduce long-term costs and ensure consistent performance. Regular inspections can help identify any issues or damage requiring maintenance or replacement.

Conclusion:

Pipe insulation is a vital component of any plumbing system, offering thermal insulation, freeze protection, and energy efficiency benefits. By understanding the function of pipe insulation and considering the qualities that make for good insulation, you can make an informed decision when selecting the most suitable insulation material for your pipes. Prioritizing efficiency and protection will not only save energy and reduce costs but also contribute to the longevity and reliability of your plumbing infrastructure. Invest in quality pipe insulation to maximize efficiency and protect your pipes for years to come.

MORE

FEATURES

- Low thermal conductivity of EPS provides increased insulation due to its closed air-filled cell structure

- When heat or cold passes through a material, it has a high capacity for thermal insulation (long-term R-value)

- Flexible in size (wall thickness) and grade (material density) based on client needs

- The typical grades used are between 10kg/m3 and 35kg/m3

- There are three standard wall thicknesses for pipes: 25mm, 50mm, and 100mm

- Easily transportable and easier to install, reducing labor and transportation costs

- All Styrocem products contain a grade A fire retardant that reduces flammability and spread of flame on the surface, making these pipe sections ideal for industrial applications.

- Water absorption is low – EPS does not absorb moisture and its properties are not affected by moisture

- EPS is age-resistant, retaining all of its properties over its lifetime

- EPS is 100% recyclable and free of CFCs and HCFCs