Are you planning your project and looking for a durable, lightweight, and cost-effective material to use? We’ve EPS foam blocks! These versatile building materials have been gaining popularity in the construction industry due to their numerous benefits. From energy efficiency to easy installation, EPS foam blocks are the smart choice for your next project. In this blog post, we’ll explore why you should choose EPS foam blocks for your upcoming build. So grab a cup of coffee and get ready to learn about the advantages of using these innovative building materials!

Introduction to EPS Foam Blocks

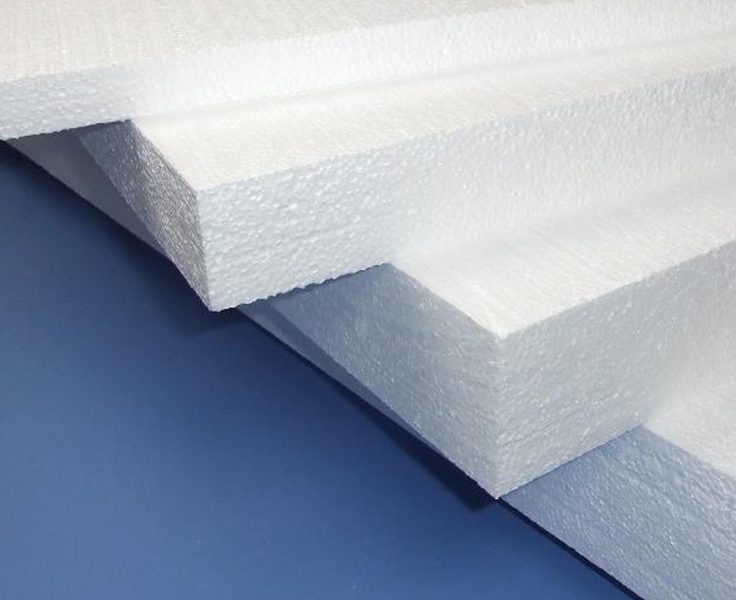

EPS foam blocks are a type of construction material made from expanded polystyrene. They are commonly used in walls, roofs, and floors because of their high insulation properties. EPS foam blocks are available in a variety of sizes and thicknesses to suit your needs.

Benefits of Using EPS Foam Blocks

If you’re looking for an eco-friendly and efficient construction material, EPS foam blocks are a great option. Made from recycled materials, EPS foam blocks are a sustainable choice for your next building project. In addition to being environmentally friendly, EPS foam blocks are also energy efficient. They can help keep your home or office cooler in the summer and warmer in the winter, which can save you money on your energy bills. EPS foam blocks are also resistant to mould and mildew, making them a good choice for humid or damp areas.

Different Types of EPS Foam Blocks

EPS foam blocks are a versatile and affordable construction material that can be used for a variety of applications. There are three main types of EPS foam blocks: expanded polystyrene (EPS), extruded polystyrene (XPS), and extruded closed-cell polystyrene (CXC).

Expanded polystyrene is the most common type. It is made by expanding polystyrene beads with steam, which causes the beads to expand and become interconnected. These are light in weight, have a low thermal conductivity, and are easy to work with. They can be cut, shaped, and glued together using standard woodworking tools.

Extruded polystyrene is denser than expanded polystyrene and has a higher compressive strength. It is made by extruding melted polystyrene through a die, which gives it its characteristic shape. XPS foam blocks are more resistant to water damage and pests. They are also more rigid, making them ideal for use in load-bearing applications.

Extruded closed-cell polystyrene is the strongest type of EPS foam block. It is made by combining melted polystyrene with a blowing agent before extruding it through a die. The resulting product has small, evenly distributed cells that give it superior strength and rigidity. XCC foam blocks are often used in structural applications where high compressive strength is required.

Cost Comparison Construction Materials and EPS Foam Blocks

There are many construction materials available on the market, each with its own set of benefits and drawbacks. When it comes to deciding which material to use for your next construction project, cost is often one of the main determining factors. In this section, we’ll compare the cost of various construction materials with that of EPS foam blocks.

Asphalt shingles are a common roofing material, and they typically cost between $3 and $5 per square foot. Metal roofing is another popular option, and it usually costs between $6 and $12 per square foot. Tile roofing is a more premium option, and it can cost anywhere from $15 to $30 per square foot.

EPS foam blocks are a relatively new construction material, but they already boast several advantages over traditional materials like asphalt shingles, metal roofing, and tile roofing. For one, EPS foam blocks are much lighter than these other materials, so they’re easier to transport and install. They’re also extremely energy-efficient, which can save you money on your heating and cooling bills. And perhaps most importantly, EPS foam blocks are very affordable – they typically cost between $0.50 and $1.00 per square foot.

Installation Methods for EPS Foam Blocks

There are three main installation methods for EPS foam blocks: mechanical fasteners, adhesive, and interlocking.

Mechanical fasteners are the most common method of installation and are typically used for exterior walls. It is first drilled and then screwed or nailed into place.

The adhesive is another option for installation. This method is typically used for interior walls since it provides a more finished look. Adhesive can be applied to both and the surface it will be mounted on.

The interlocking method is the strongest of the three methods and is often used in commercial construction projects. Interlocking EPS foam blocks fit together like puzzle pieces and are held in place with tape or glue.

Tips for Choosing the Right EPS Block for Your Project

There are a few things to consider when choosing the right EPS block for your construction project:

1. The density of the EPS block. The density of the EPS block will affect the strength and durability of the finished product. Higher-density EPS blocks are more resistant to crushing and impact damage, making them ideal for projects that will see a lot of foot traffic or other wear and tear. Lower-density EPS blocks are lighter and easier to work with, but may not be as durable in the long run.

2. The size of the EPS block. EPS blocks come in a variety of sizes, so it’s important to choose one that is appropriate for your project. If you’re working on a small project, like a playhouse or garden shed, you won’t need a large block. Conversely, if you’re working on a large commercial building, you’ll need something much bigger.

3. The amount of insulation you need. Another factor to consider is how much insulation you need for your project. Some types of construction, like soundproofing, require more insulation than others. Make sure to take this into account when choosing your EPS block so that you don’t end up with too much or too little insulation for your needs.

4. The climate you’re working in. The climate also plays a role in choosing the right EPS block for your project. If you’re working in an area with extreme temperatures, you’ll need an EPS block that can withstand those conditions without

Conclusion

EPS foam blocks are becoming increasingly popular in construction projects due to their lightweight, cost-effective, and environmentally friendly nature. When compared with other building materials, such as concrete blocks or wood frames, these foam blocks offer superior insulation properties that can help you save money on energy costs for many years to come. With so many advantages over traditional building materials, it is no wonder why these are becoming a go-to choice for many contractors and DIYers alike!