Explore the diverse and innovative uses of Thermopore (Expanded Polystyrene) in construction, packaging, cold chain logistics, civil engineering, art, and more. Discover how this lightweight and thermal insulating material plays a pivotal role in various industries, promoting energy efficiency and sustainability while ensuring the safe transportation of delicate items and enhancing water safety with flotation devices. Unleash the potential of Thermopore and its remarkable versatility in shaping a greener and more efficient future.

Introduction

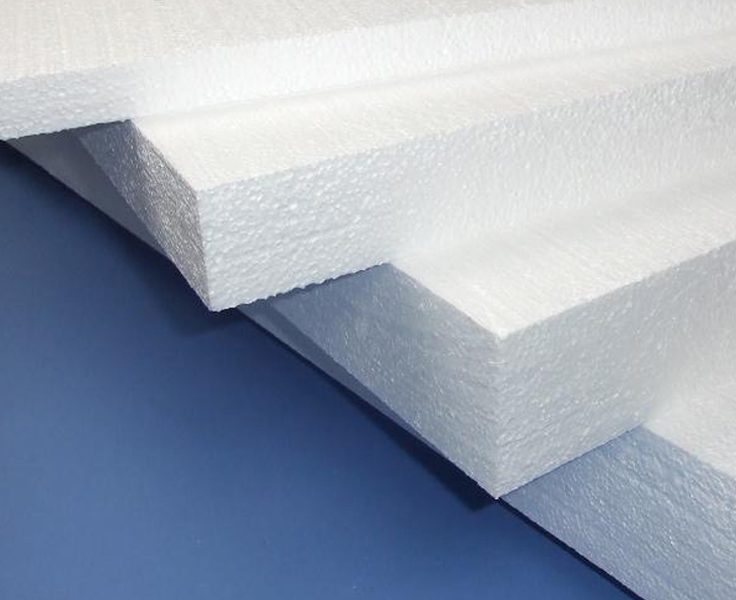

Thermal insulation is a crucial aspect of modern construction and various industries. One material that has gained immense popularity for its exceptional thermal insulation properties and versatile applications is Thermopore, also known as Expanded Polystyrene (EPS). This lightweight and rigid cellular plastic material has revolutionized the way we insulate buildings. It protect sensitive products during transportation, and even manufacture flotation devices. In this comprehensive blog post, we will delve into the wide array of uses of Thermopore, exploring its applications in construction, packaging, cold chain logistics, civil engineering, and more. Let’s discover the remarkable world of Thermopore and how it continues to shape and enhance various industries.

1. Construction Industry: The Backbone of Thermopore Uses

One of the primary and most prominent uses of Thermopore lies in the construction industry. It’s high thermal resistance and lightweight nature make it an ideal material for thermal insulation in buildings. Thermopore is commonly used in walls, roofs, floors, and foundation systems to maintain indoor temperatures, reducing the need for excessive heating or cooling. By minimizing heat transfer through conduction and convection. Thermopore helps to create energy-efficient and sustainable structures, thereby lowering energy consumption and costs.

Furthermore, the ease of installation and adaptability of Thermopore allows builders and contractors to work efficiently, cutting and shaping the material to fit any design requirements. Additionally, the moisture resistance and chemical inertness of Thermopore ensure its longevity and durability, making it a reliable choice for construction projects in various weather conditions.

2. Packaging Solutions: Protecting Delicate Items

Thermopore’s lightweight and cushioning properties have made it a go-to material for protective packaging solutions. In the packaging industry, delicate items such as electronics, glassware, and appliances require extra care during transportation to prevent damage. Thermopore, with its ability to absorb shocks and impacts, provides a secure and reliable protective layer, safeguarding these items from potential damage.

Moreover, Thermopore’s moisture resistance ensures that the packaged products remain unaffected by external weather conditions during transit. As a cost-effective and efficient solution, Thermopore has become a staple in the packaging industry for ensuring the safe delivery of fragile goods.

3. Cold Chain Logistics: Preserving Temperature-Sensitive Products

In industries like pharmaceuticals and food, maintaining a controlled temperature during transportation and storage is critical to preserving the quality and efficacy of temperature-sensitive products. Thermopore’s exceptional thermal insulation properties make it an excellent material for manufacturing cold-chain packaging.

Cold chain packaging, frequently employed in the transportation of vaccines, medicines, and perishable food items, heavily depends on Thermopore to maintain stable temperatures and shield the contents from temperature fluctuations. By ensuring that products consistently remain within the required temperature range, Thermopore significantly contributes to the overall success of cold chain logistics, ensuring the safe and effective delivery of these critical items.

4. Civil Engineering: Geofoam for Lightweight Fill

Thermopore has found its way into civil engineering applications as geofoam, a lightweight fill material used to reduce the load on soil and offer stability to structures. Traditional fill materials like soil or rock can exert excessive pressure on underlying soils, leading to settlement and instability issues. Geofoam, on the other hand, provides a lightweight alternative that distributes loads more effectively.

Geofoam is commonly used in road construction, embankments, and slope stabilization projects. Its lightweight nature not only minimizes the stress on the soil but also facilitates ease of handling and installation, resulting in cost and time savings during construction.

5. Flotation Devices: Ensuring Safety on Water

The buoyant nature of Thermopore makes it an essential component in the manufacturing of flotation devices. Life jackets, buoys, and floating platforms rely on Thermopore’s ability to stay afloat in the water while providing support and safety to users.

In water sports and marine industries, these flotation devices are indispensable for ensuring the safety of individuals and cargo. Thermopore’s buoyancy and resistance to moisture make it an ideal material for such applications, contributing to water safety and rescue operations.

6. Art and Decorations: Unleashing Creativity

Beyond its functional uses, Thermopore has also found a place in the world of art and decorations. Its ease of shaping, lightweight nature, and availability in various sizes and densities make it a favourite material for artists and designers.

Thermopore is utilized in creating sculptures, stage sets, art installations, and other creative projects. Artists can carve, mould, and paint the material to bring their imaginative visions to life. Additionally, its affordability and accessibility have democratized the art world, allowing artists of all levels to explore their creativity without breaking the bank.

Conclusion

Thermopore, or Expanded Polystyrene, continues to showcase its versatility and indispensability across a myriad of industries. From revolutionizing thermal insulation in construction to safeguarding delicate items during transportation and even enhancing creativity in the world of art, Thermopore’s remarkable properties have left a lasting impact. Its lightweight nature, thermal insulation capabilities, and resistance to moisture and chemicals have made it a go-to material for a wide range of applications.

As industries continue to evolve and sustainability becomes paramount, the use of Thermopore is expected to grow further. Its role in promoting energy efficiency, reducing waste, and enhancing safety make it a critical component in building a greener and more sustainable future. As technology advances and new applications arise, the potential for Thermopore’s uses is expected to expand, solidifying its position as a reliable and versatile material across various sectors.